Auto phosphating of MS Shell

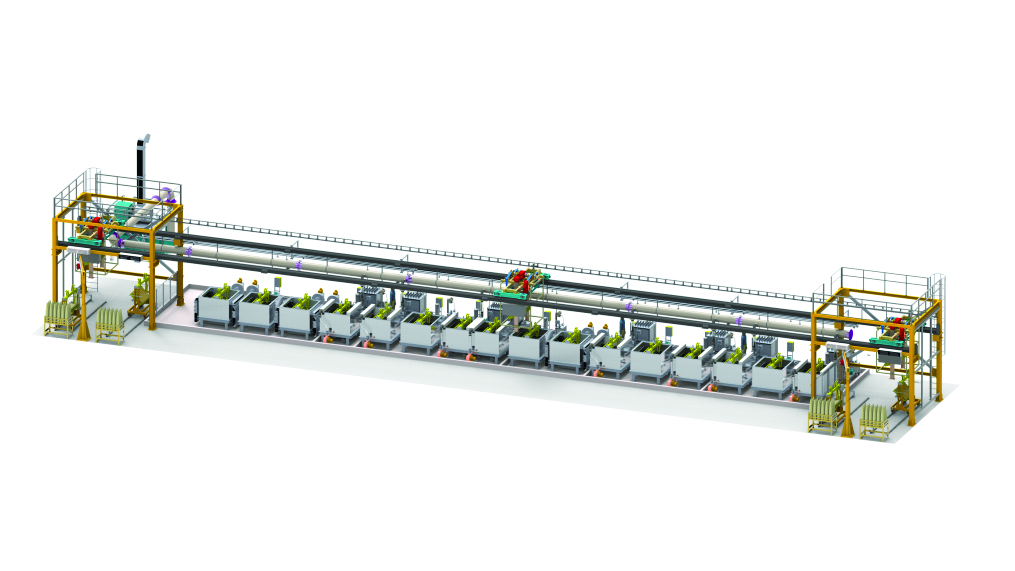

Cybernetik’s fully automated phosphating solution for MS Shell delivers uniform surface treatment through complete pre and post-phosphating processes.

Our solution integrates a self-contained, continuous, and fully automated phosphating plant, ensuring optimal performance at every stage. The system incorporates SCADA for recipe management and data reporting, providing seamless control and real-time monitoring. With a user-friendly HMI and built-in safety features, the solution efficiently handles all essential processes such as degreasing, rinsing, de-rusting, drying, activation, chromate rinsing, and sealing, ensuring a high-quality finish with consistent results.

Grow Your Business

Bring the power of industrial automation to your wind energy business.

Assembly Line

System Features

- Fully automatedand self-contained phosphating solution to deposit a uniform phosphate film on MS shells.

- Pre- and post- phosphating operations: Degreasing, rinsing, de-rusting, drying, activation, chromate rinsing, sealing.

- Multiple Transporters for transfer of in-process shells between stations.

- Dedicated Tanks for different operations.

- SCADA System recipe management and data reporting.

- System interlock and emergency stop for safety

Technical Specifications

| Parameter | Value |

|---|---|

| Throughput | 60 shells/hr |

| Coating Thickness | 50 to 150 µm |

| Shell Dimensions | Max. 1000mm (L)X 200mm (dia) Min. 400mm (L) X 100mm (dia) |

| Footprint | 10 x 50 x 5.5 m Customizable based on number of tanks used |

| Water Pressure | 3.0 ±0.75 Kg/cm 2 (less than 100µS/cm conductivity) |

| Compressed Air Pressure | 5~7 Kg/cm 2 (oil free) Water content Ratio: ± 0.2 PPM |

| Electrical Power | |

| • Drive Motor | • 415 V ± 10 % x 50 Hz ± 2 % x 3 Phase x 3 WIRE |

| • Control Panel | • 415 V ± 10 % x 50 Hz ± 2 % x 3 Phase x 4 WIRE |

| • Illumination | • 230 V ± 10 % x 50 Hz ± 2 % x 1 Phase x 2 WIRE |

About Us

Headquartered in India with two design offices and four manufacturing plants, Cybernetik provides automation and robotics solutions to industries across the world.

We tackle complex industrial challenges for leading international brands, by providing expert solutions employing innovative approaches and use of advanced technologies.

HQ - India

Cybernetik Technologies Pvt. Ltd.Gate No. 365, Urawade, Mutha Road, Opp. Indo-German Technology Park, Pune - 412108. Maharashtra, India.

Email: [email protected]

0+

Systems Installed Worldwide

0+

Satisfied Customers